Package fragility is a concern for most of our clients. We focus on not only the beauty but efficacy of packaging products for their intended uses. It is our responsibility to evaluate each package's ability to protect the product inside throughout the handling, distribution and storage process. Simulating the conditions of the distribution and storage environments allows us to be confident that your products arrive the hands of consumers in good condition. We perform a round-up of popular testing methods to check the safety and durability of packages.

A box too weak might puncture or collapse. On the other hand, an excessive box means you pay extra for material and add to environmental wastage. Grammage and thickness are the two most fundamental properties of the corrugated fiberboards that determine the quality of the box.

The Mullen (bursting) test is used as a general guide to the strength of corrugated board. It checks the toughness of the walls of the corrugated board when subjected to force or pressure. We determine bursting strength using a digital hydraulic paper burst tester as shown.

Edge crush test is a measure of the load bearing capability of corrugated fibreboard to loads acting parallel to the fluting. In the test, force is applied to one side of the box, perpendicular to the ridges, until the box gets crushed. We test to Chinese Standard GB/T6546-1998.

Compression testing relates to stacking or crushing of packages, particularly shipping containers. It gives us a good idea of how many boxes can be stacked together without damaging the contents of the lowermost box. The boxes are tested in different orientations.

It is a pre-shipment test ensuring that the product will reach its final destination without any issue or problems. We simulates the freefall of package on its corners, edges and surfaces to see how the product and packaging can withstand normal shipment handling.

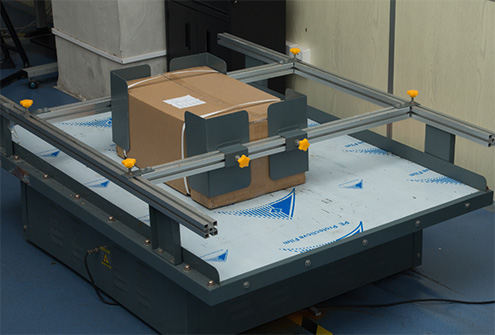

It is used to identify the ability of a package to withstand environmental vibrations. Through the use of electromagnetic shaker, tests are performed in a fixed-frequency sinusoidal wave that show how the package react to the vibrations that they will suffer during handling and transportation.

* You can unsubscribe at any time using the link in our emails.